SBS Expands Utility DataHub™ and Automated Utility Design™ to Enable Digital Construction for Utilities

Our mission at SBS is to provide integrated design solutions for utility organizations. Over the last many years, our focus has been all about bridging the platforms of CAD, GIS, and Enterprise Asset Management (EAM)¹. CAD and GIS products from Autodesk and Esri are adding more and more support for Building Information Modeling (BIM), which has allowed SBS to include support for BIM within Version 3.0 of our Utility DataHub™ (UDH) product. We are pleased to announce that this new version of UDH now provides secure access to the Autodesk Construction Cloud. [Note: Since utilities do not primarily construct buildings, we like to use the term “Digital Construction,” rather than BIM, which you will notice throughout this article.]

Our products have several core capabilities that have helped us enable digital construction. One of the primary enablers is the use of a model-based design. Model-based design is the inherent capability within our Automated Utility Design (AUD) product that allows us to represent real-world objects. Elements designed in AUD have unique identifiers, graphic components, properties, and inter-object relationships, such as network connectivity, which are represented by the AUD object definitions.

A strong model becomes the foundation for the creation of digital twins, which can be used to support many of the core elements of digital construction such as model coordination and clash detection, constructability reviews, material traceability, as-built management, and strategic asset management.

How does it work?

For an organization that uses our AUD and UDH products, the workflow is quite straightforward and very similar to our current workflows.

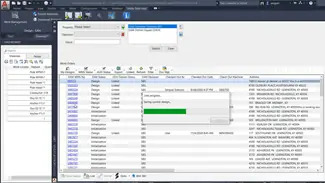

At job initiation, the job is assigned to a designer. The designer is presented the work orders from the EAM that are actionable within the AUD product. The job is presented in a work order browser which is just how work is initiated in AUD and UDH today. When the design is linked to the work order, UDH connects to Autodesk Construction Cloud (ACC), creates the appropriate folders, and checks the drawing into the ACC repository as shown in the screenshot below.

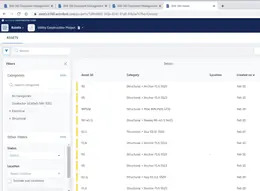

The document can be viewed in the Autodesk Construction Cloud Document Management repository.

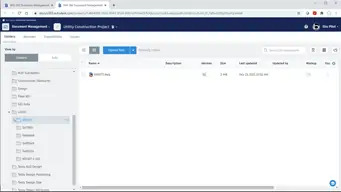

UDH allows you to create versions in ACC drawing management as shown in the diagram below.

These workflows are very similar to the workflows put in place when implementing AUD and UDH for a typical integrated utility design solution. Once the information is in the Autodesk Construction Cloud however, the core capabilities can be made available to support the digital construction workflows facilitated by Autodesk Construction Cloud.

What Can Integrated Digital Construction Do for My Utility?

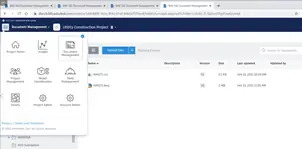

Though still in the early stages, digital construction, particularly for utilities, already provides many definite benefits. First, having the digital representation of the assets in a shared, accessible, cloud-based repository provides an open way of updating and managing the asset management package created during the design process. An asset tracking representation in Autodesk Construction Cloud is shown below.

Second, leveraging Autodesk’s Document Management facilitates an advanced digital work packaging that can incorporate not only the base design, but all the other construction documentation associated with a project. This also includes the necessary version management to address change management. This is a significant opportunity for enabling collaboration between the office and the field.

As we look to the future, the fundamental building blocks of traditional BIM also apply. These are shown in the figure below, courtesy of Autodesk.

Of all these capabilities, perhaps the most interesting to us here at SBS is the ability to generate insights into the construction process via the use of data analytics. Distribution utilities in particular can easily create tens of thousands of jobs a year, which can provide a tremendous amount of data that can be used to create opportunities for improved business performance.

*****

We look forward to hearing from you and learning more about how you are starting to use your design data to improve your construction processes. Thanks for reading our post.

¹EAM, as used in this post, can take on many different names based on vendor products and capabilities. These can include Enterprise Resource Planning (ERP), Work and Asset Management (WAM), and Work Management Systems (WMS).