SBS Automated Utility Design™ supports flexible and efficient renewable energy system design and construction for Atwell LLC.

Dennis Beck, President/CEO

Last year we shared a blog post on how Atwell LLC uses our Automated Utility Design (AUD) product solution to design wind farm collector systems. The post was based on a presentation the Atwell team shared with our Peer Utility Group user conference in 2019 about projects they were delivering in Missouri and Illinois. This past Thanksgiving, as I was driving with my family through Missouri on my way back to Colorado, I noticed a tremendous number of wind turbines dotting the landscape, and it made me want to learn what has happened over the last 18 months.

I reached out to Jesse Zellmer and Joe Snodgrass of Atwell LLC and was pleased to learn they have extensively grown their renewable practice over the last two years and have now used AUD to design renewable projects in ten states across the United States. This post shares information about a number of new things they have been able to do with AUD across multiple areas of their design workflows.

First, the Atwell team expanded their intelligent design work to support solar systems in addition to the initial projects they have done with wind farms.

Solar systems, like wind farms, need to optimize their collector systems. Many variables go into creating the best design such as geographic constraints, including terrain, road crossings, and property rights, as well as the numerous factors that impact engineering performance. The screenshot above shows a solar farm that was laid out using AUD. The geographic constraints in the background map and the configured validation rules for generator racking and combiner names are visible, helping with that optimization in design.

Next, Atwell found the intelligent models created in AUD also provide tremendous automation capabilities as the systems go through design changes. A project in South Dakota was initially designed with four feeders. However, plans evolved to evaluate an alternate, more efficient design that only had three feeders. The design changes were quickly implemented in less than a day. From there it was possible to generate a bill of materials and cost estimates that allowed the team to evaluate and ultimately design a better system that would ensure a profitable project. This example shows the modeling power of AUD being leveraged to make a design change process more efficient.

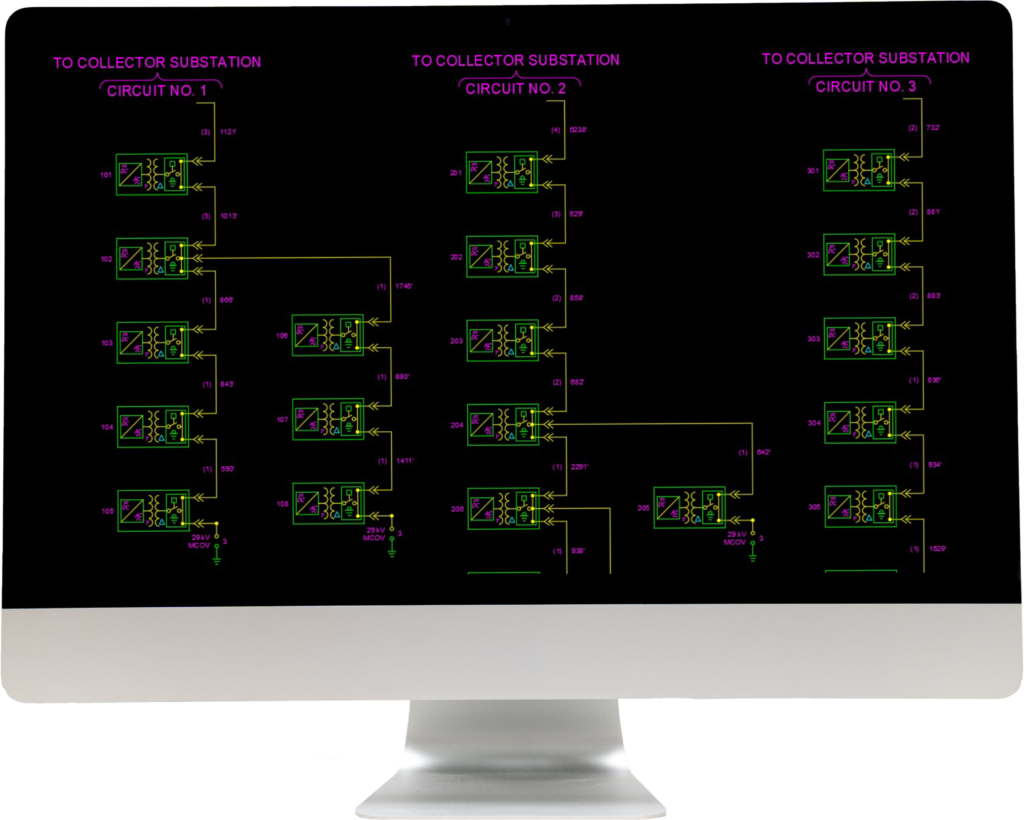

One of the advanced features more recently added to AUD is the ability to auto-generate electrical one-line diagrams. The dynamic nature of the AUD blocks, directly linking the text (cable size, length, and name of inverter station) to feature attributes in the AUD model, ensures that the one-line always agrees with the layout design. The Atwell team has leveraged these capabilities to automate this process in the creation of their electrical diagrams. The screenshot above shows AUD being used to make the post-design/construction print process more efficient.

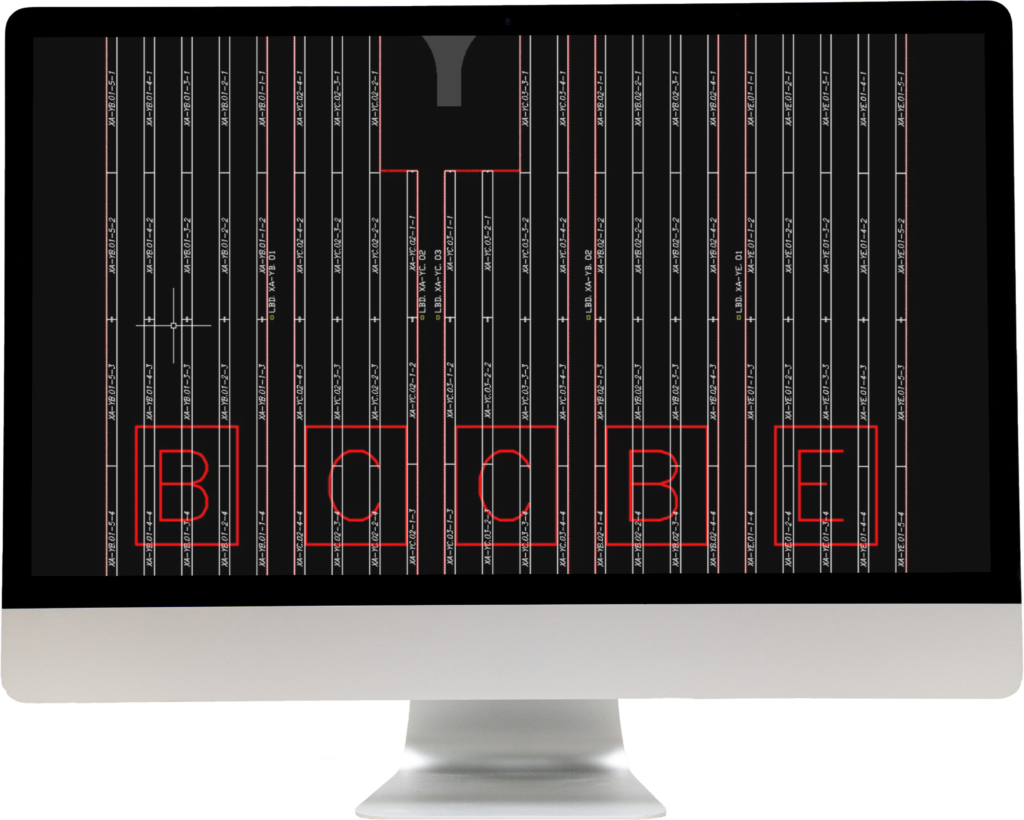

This leads directly to AUD being able to support simple, powerful, and structured ways of providing highly accurate information to the construction phase of a project. The use of BIM (Building Information Modeling) has been commonplace in the construction of buildings for many years, but it is still in its early stages for infrastructure design.

That’s now changing in the world of renewable energy. We see increased needs for accurate depictions of assets, sequenced in a way that supports an efficient set of construction processes. This includes detailed schedules of equipment and sequential positioning of devices throughout the collection system.

Because these systems change frequently during the design phase, it was common to spend many days doing clean up and manual reviews of drawings to ensure error-free, accurate construction documentation. AUD’s robust modeling capabilities provide detailed, intelligent representations of these objects to ensure that the relevant intelligent design data can be leveraged in support of a changing design process. These BIM-enabling capabilities provide the most accurate and complete information to the construction crews that are installing these systems, all done in a highly automated manner.